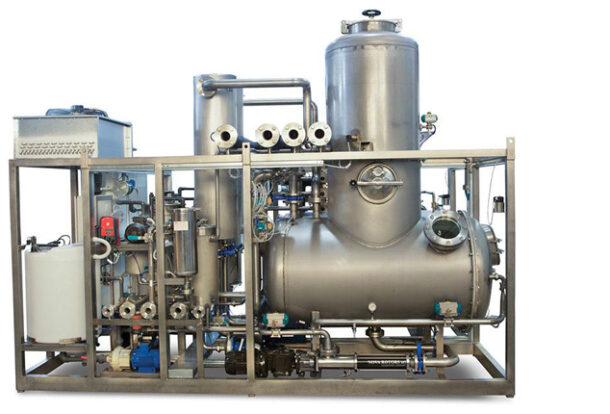

Zero Liquid Discharge Plants

An effective and efficient industrial treatment process minimizes the discharge of wastewater and maximizes water recovery. Zero liquid discharge technologies assist industrial plants in meeting discharge and water reuse requirements, helping them to:

Description

Zero Liquid Discharge Plants

An effective and efficient industrial treatment process minimizes the discharge of wastewater and maximizes water recovery. Zero liquid discharge technologies assist industrial plants in meeting discharge and water reuse requirements, helping them to:

- Meet stringent cooling tower blowdown and flue gas desulfurization (FGD) discharge regulations

- Treat and recover valuable products from waste streams

- Better manage produced water

Various technologies are commonly used to achieve complete Zero Liquid Discharge (ZLD) status. These include ultrafiltration, reverse osmosis, evaporation, crystallization, salting out and drying. WATERTEC uses these proven technologies in industrial wastewater and effluent treatment applications in volume reduction and zero liquid discharge:

- Chemical Processing and Manufacture

- Industrial and Municipal Landfill

- Mining and Ore Processing

- Oil & Gas Field Produced Water

- Oil & Gas Refining

- Power Generation

- SAGD (Steam Assisted Gravity Drainage)

Design

At WATERTEC, our treatment designs can result in extensive recoveries of both solid and liquid phase outputs. With notable success in effluent treatment, our clients have benefited from an effective approach with our operational 'Zero Discharge' plants located throughout the country.

Benefits

- All solid and liquid phases from this WATERTEC plant design are recoverable.

- WATERTEC plant design is mechanical (non-biological) with just a few process stages, thus benefiting from relatively low capital costs.

- Financial returns are further improved by reducing waste volumes and the associated disposal costs and by savings accrued from recycling of feed and water reuse.

- The system is highly automated, with a relatively short operator training time, also reducing operating costs.

- We have installed this technology at many sites across India.

Customized Solution

Selection of a plant depends on application, water quality and water consumption. Our water experts are at your service to ensure the best customized solution.

?>

?>